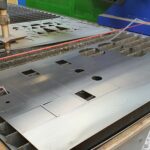

After we finished our 3D drawing of the oil lamp in an Inventor program, we first, had to change a codex file of parts soo the program for the plasma cutter was able to read them. Then we moved parts in a special program for a CNC plasma cutter, and we deployed them onto a plate where they will be cut outside. When we had them finished we had to make a program with a text file for CNC plasma cutter or soo called G-code. After we changed our program into G-code we moved it to a USB flash drive. With that, we were able to start a program on a CNC plasma cutter, but we also made parts double soo that each one of us will be able to weld its own oil lamp. When the program came to an end we took out cut parts with a magnet. Then we had to simply put away some access material that the CNC plasma cutter made, and we did that with a belt grinder. After grinding parts were ready for welding and our school day came to an end.