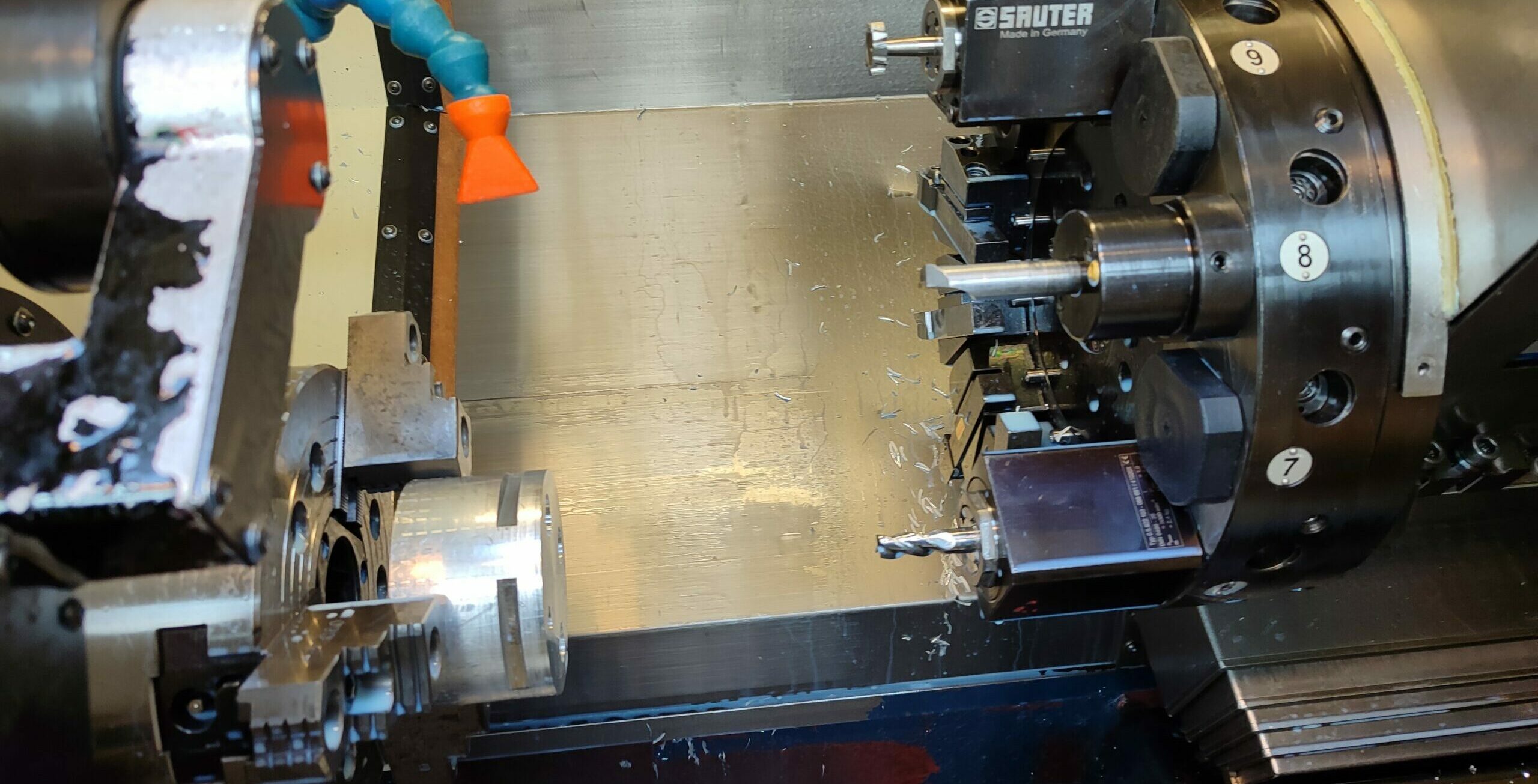

This week was the most interesting because we fina lly started learning about CNC machines. On Monday, we got to know the machine. We were given instructions for use and had to set up the CNC lathe by ourselves, without the presence of the professor, in such a way that it was only necessary to load the program and make the product, which had to be within the tolerance limits. We had quite a few problems, as the lathe was from another manufacturer and had a different work process, but we successfully resolved them with the professor’s help. After choosing the right lathe head, choosing the correct diameter and material of the stock, and calibrating all the tools we needed, it was time to test the program. We made the program ourselves, so we didn’t initially believe in our abilities and took our time for the first piece. We successfully made the first piece without any problems; it just wasn’t within the proper tolerances. Because we took too much time on the first piece, we ran out of time on the second and third pieces. We managed to make it, but that’s why there was a problem with the tolerances.

For the second exercise, we made a program for a lathe in MasterCam, where it was necessary to use the C-axis. It is more complex than it seems because the computer thinks differently than we do. But with time, I learned that, too, and made a program using C-axis. We transferred the program to the CNC lathe and tried to make the product, but it didn’t work. We rechecked everything and tried all the valuable ideas but failed. In the end, we concluded that the error was in the Postprocessor. Not long ago, they updated it, but they deleted the old program, which worked 99% of the time.

In the following days, I created a program for my product for the final assignment, which fortunately did not require drilling a hole through using the c-axis. I also successfully did the part in the following week.